WHAT WILL YOU LEARN?

Sampling precision and accuracy at the mine, plant and laboratory The influence of sampling and the importance of QA-QC on reconciliation results The history of the Mine Call Factor Difference between reconciliation factors and reconciliation indicators How to define reconciliation nodes and reconciliation relationships Reconciliation at different stages of the mining project Sources and causes of observed deviations in reconciliation Difference between proactive reconciliation and reactive reconciliation The risks of 'illusory reconciliation'. The best sampling systems for mine-to-mill reconciliation How to analyze and interpret the results of a reconciliation system How to develop a proactive reconciliation model How to develop a code of reconciliation best practice Case study 1: optimizing mine-to-mill reconciliation at a gold mine Case study 2: a case of illusory reconciliation at a copper and gold mine Exercise: calculation of reconciliation indicators and analysis of a reconciliation system

TARGET AUDIENCE

Exploration and grade control geologists Mining engineers, process engineers and metallurgists Mine reconciliation officers QA-QC officers Metals accounting officers Presidents, vice presidents and operations managers Mining technicians and students

WHAT WILL YOU LEARN?

Sample accuracy and precision in the mine, The influence of sampling and the importance of QA-QC on reconciliation results The history of the 'Mine Call Factor' Difference between reconciliation factors and reconciliation indicators How to define reconciliation nodes and relationships Reconciliation at different stages of the mining project Sources and causes of observed deviations in reconciliation Difference between proactive reconciliation and reactive reconciliation The risks of 'illusory reconciliation' The best sampling systems for 'mine-to-mill' reconciliation How to analyze and interpret the results of a reconciliation system How to develop a reconciliation model How to develop a code of good reconciliation practice How to develop a code of good reconciliation practice Case study 1: Optimizing "mine-to-mill" reconciliation at a gold mine Case study 2: A case of illusory reconciliation at a copper and gold mine Exercise: calculating reconciliation indicators and analyzing a reconciliation system

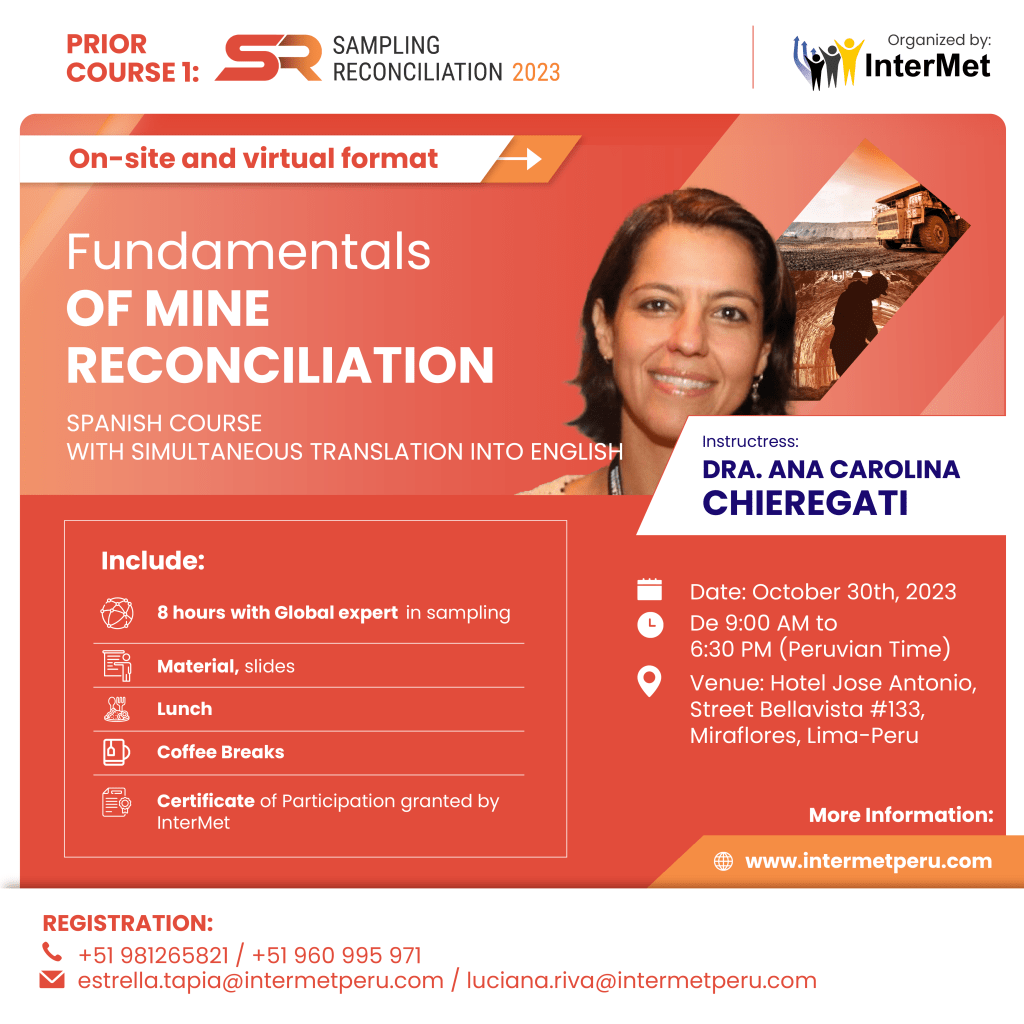

DRA. ANA CAROLINA CHIEREGATI

Ana Carolina is a mining engineer, master and PhD in Mineral Engineering from the University of Sao Paulo, and post-doctorate in sampling from the University of Aalborg, Denmark. Since 2002, she has been a professor in the Department of Mining and Petroleum Engineering at the University of Sao Paulo and is responsible for the disciplines of Mineral Exploration, Sampling, Quality Control and Reconciliation. With 18 years of experience in sampling and reconciliation, she has taught in Brazil, Argentina, Peru and Australia. In addition, he has published several technical articles and book chapters, and has participated in several projects in Brazil, Argentina, Chile, Peru, Honduras, USA, Mexico and Mongolia, related to mining reconciliation and optimization of sampling procedures in gold, iron, zinc, copper, lead, nickel, niobium, phosphate, tin, vanadium, rare earths and bauxite mines.

Full CV:http://lattes.cnpq.br/2179900906147256

INVESTMENT : USD 350

START DATE :

OCTOBER 30, 2023

HOUR :

9:00AM To 6:30PM (Peruvian Time)

MODALITY :

ONLINE AND PRESENTIAL COURSES

PLACE: HOTEL JOSÉ ANTONIO, CALLE BELLAVISTA #133, MIRAFLORES, LIMA - PERU